Tooling & Gauging Control (Back)

This module can be used in either stand-alone format or in conjunction with other 1st Manufacturing modules.

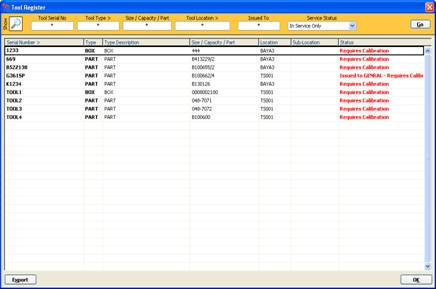

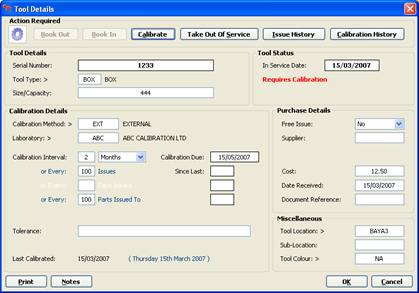

The main features provided by the module are to control the status of all your Tools & Gauges, when they were last calibrated and which are now due for calibration.

Probably the major cost benefit provided over manual and other forms of control is in reducing the number of items requiring calibration by tracking how many days of Shop Floor use they have had, whilst time held within the Tooling & Gauging Department can be treated as not counting towards their service days between calibrations - this can considerably reduce the volume of items requiring calibration.

Summary Specification:

Information recorded on all Items:

Tooling Location

Tooling Colour

Issue History

Calibration History

Tool No / Serial No Description

Tool Type / Group Calibration Method

Tool Size Tolerance

Ext. Calibration Lab. (if relevant)

Calibration Interval in Days and/or Issues

and/or Days of Issue

Purchase Details: Supplier Cost

Date Purchase Doc.Ref.

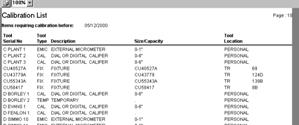

Reports & Enquiries Available:

Items due to be Calibrated Inspectors

Items due to be Calibrated Inspectors

Tool List Employees

Calibration Records Calibration Instrs

Tool Locations Calibration Labs

Tool Suppliers Calib’n Results

Detailed Individual Tool Sheet Tool Types

Out of Service Items Tool Conditions

Issued Items Tool Colours

(showing Job & Employee)