Shop Floor Data Capture and Time Recording (Back)

Whilst this 1st Manufacturing module can be used in stand-alone form for Employee Attendance it really becomes of most benefit when used in conjunction with 1st Manufacturing Works Orders for Job Costing and for the monitoring of Job Progress ( Operation by Operation ).

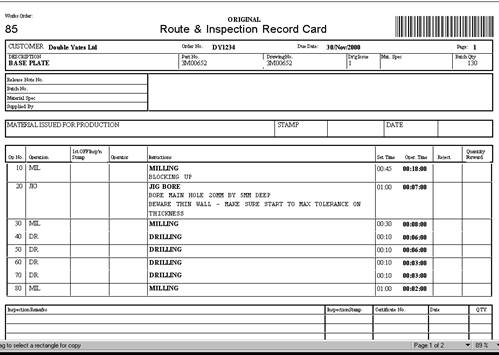

Each Employee is provided with a Bar Coded Employee Card and every Works Order has a Bar Coded Route Card:

These Bar Codes are read by our Shop Floor Data Capture Terminals ( that utilise a standard on-line P.C. coupled with a Touch Screen Monitor and Laser Bar Code Scanner) to ensure information can be quickly and easily captured. No keyboard or ‘mouse’ use is required.

This combination of equipment and 1st Manufacturing Shop Floor Data Capture software enables easy use by the Employees to:

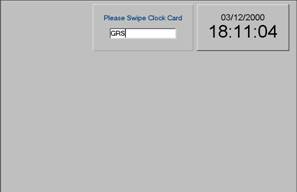

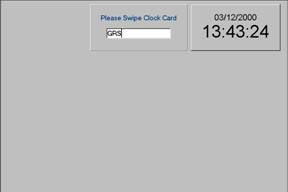

- Book onto, and off, the premises / shift for Time and Attendance requirements

- Book onto, and off, individual Works Orders (by Operation if required)

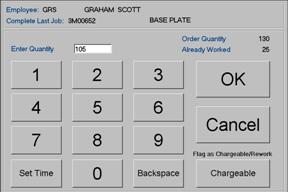

- Record number of Parts manufactured, whether Operation is complete, and the split between Set-Up and Operation Time (if required)

- Record (if required) Non-Chargeable Times and Reasons (e.g. Waiting for Material, Waiting for Setter, Machine Breakdown, Waiting for Tooling, etc.)

- Enquire on their Booked Shift Hours

From the Company’s point of view the major benefits of a Real-Time Shop Floor Data Capture system are:

- Up to the minute visibility on the progress of any Job and its comparison to the Schedule

- Interrogate what Operations are currently being worked on

- Exception reporting of any Operations that are falling behind Schedule

- View the Job Costing time value being accumulated against a Job and compared to the Quotation - Operation by Operation

- See what Employees are On-Site and what Jobs they are currently engaged on

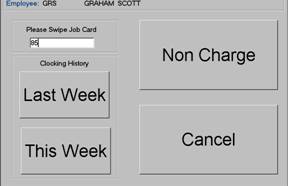

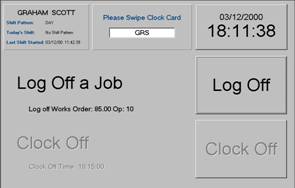

The Time Swiping Process is a simple 1, 2, 3 operation…..

Log ONTO a Job / Operation Log OFF a Job / Operation

1

1

Swipe the Employee’s Card Swipe the Employee’s Card

2

2

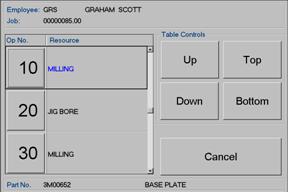

Swipe the Route Card

3

3

Press the ‘Operation No’ to be worked on Enter the ‘Quantity’ Produced

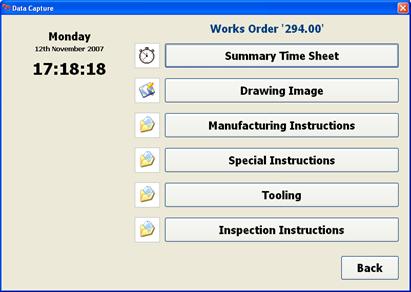

1st Manufacturing’s shop floor data capture also allows the following activities to be performed.

Summary timesheet gives a view of all time spent against a works order

Drawing image gives the operator a view of the drawing for the works order they are working on.

Manufacturing instructions allows them to view the manufacturing instructions for the job they are currently log onto.

Special instructions give other information specific to the job that are working on.

Tooling shows the tools that are allocated to this particular job

Inspection instructions show the inspection checks that need to be carried out on this job.

These screens are specifically designed to be used in a manufacturing environment and can even be operated with gloves.