Scheduling (Back)

This 1st Manufacturing module can only be used in conjunction with our Sales Order Book, Works Order, Quotation and Manufacturing Instruction modules.

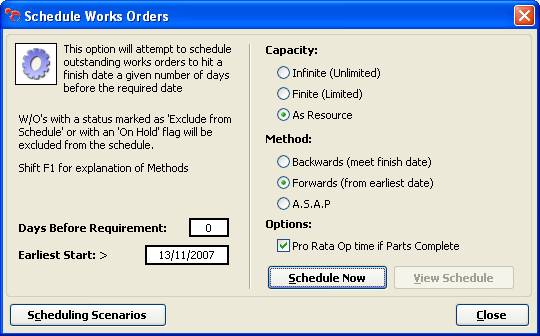

All Works Orders (and underlying Sub-Assemblies or Components of an Assembly) are expanded to their constituent Operations and Scheduled using Manufacturing Instruction based Operations and Times are if present - otherwise Quotation details are used.

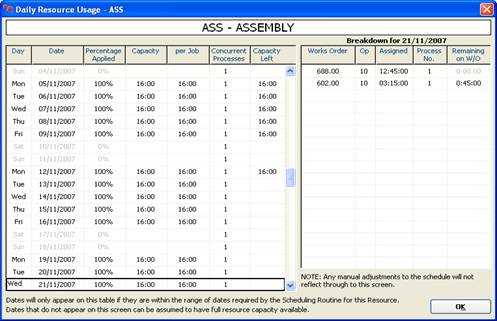

All these Operation details are then amalgamated, by day, to provide the overviews of Planned vs Available Capacity. Available Capacities are specified through Resource Codes which represent the various Machines or Processes within your company.

Each Resource Code is specified with a Daily Overall Capacity Available (No. of Machines x Normal Working Hours per Day) and Maximum Capacity to be Planned against any one Job per Day (Normal Working Hours per Day).

In addition a Percentage is specified against each day of the week which reflects each days available capacity as a percentage of the Normal Working Hours (e.g. Monday to Thursday may be 100% with Friday being 60% and Saturday being 20% - thus representing a typical early finish on Fridays and Morning Shift on Saturdays).

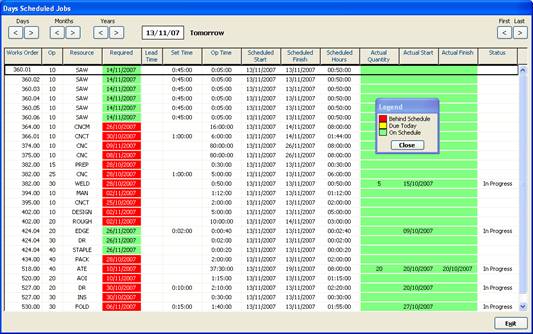

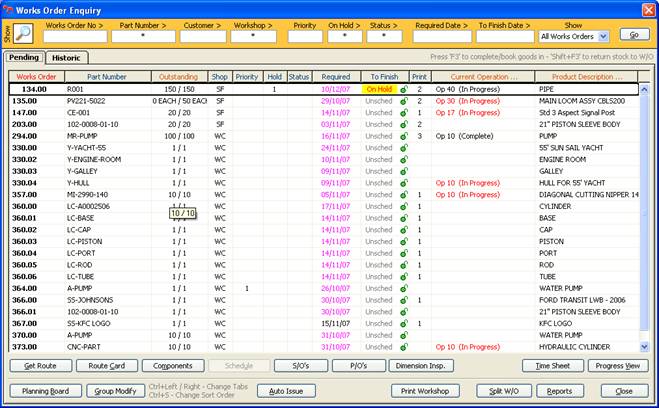

All Scheduled Works Orders are viewed and monitored from a Works Order ‘Command Screen’ from which it is possible to see:

- Planned Start Dates (in RED if late) and Finish Dates

- Source of Scheduling Data for each W/O (i.e. Manufacturing

Instructions or Quotation or Not Scheduled)

- ‘Drill down’ to see Customer Order make-up of Works Order

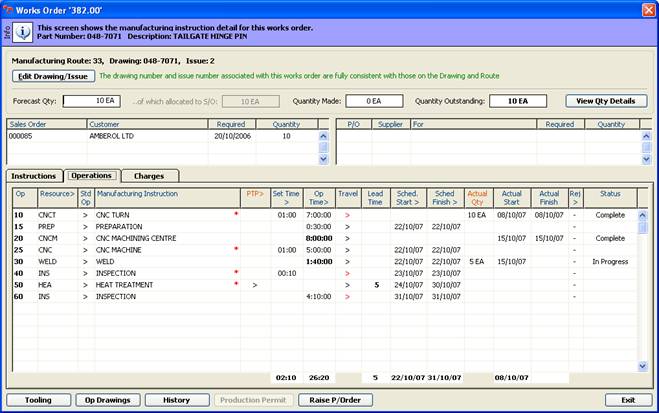

- ‘Drill Down’ to see Operation and Time make-up of Works Order

- Graphical Calendar based Plan showing days when each Operation is

Planned and (in a different colour) the Actual Progress alongside

- Detailed record of Time Bookings to each Operation by Employee

-‘Drill Down’ to all associated Purchase Orders for any Works Order

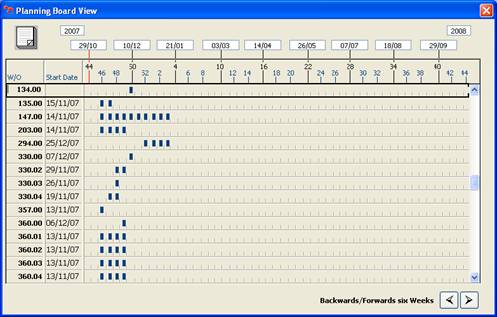

- An overview graphical Calendar based Plan of which weeks each W/O is Scheduled

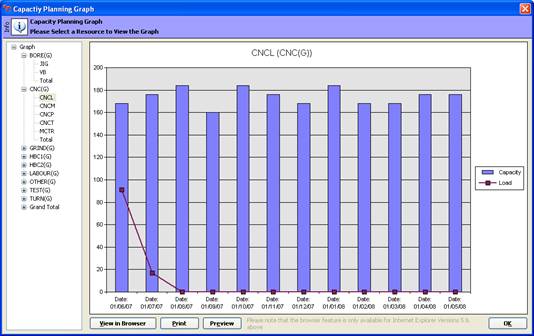

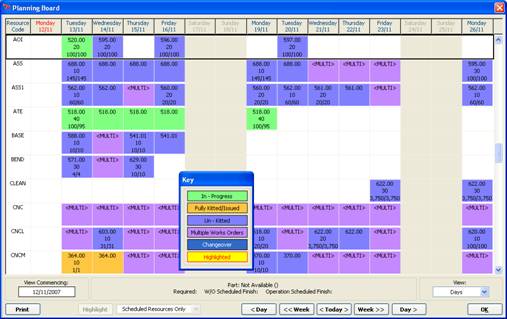

- A graphical view of Scheduled Requirement for each Resource

Group, against available Capacity, that can then be ‘drilled down’ to

see the Planned W/O’s for that week

It is also possible to:

- Re-Schedule an individual Works Order to a different Required Date

- Print an individual or group of Route Cards

The Major Benefits of this module are:

- The ability quickly and accurately to calculate and view a plan aqainst which management can plan and

prepare their actual production

- Production of ‘Work To summaries by Resouce code for the shop floor Supervisors so they, and

their Team, have vision of, and can plan for, work coming through to their Section and its relative importance

and priority with other work

- Customer queries on progress of their Jobs easily answered via the Actual vs Plan graphical display