Raw Materials & Finished Parts Stock Control (Back)

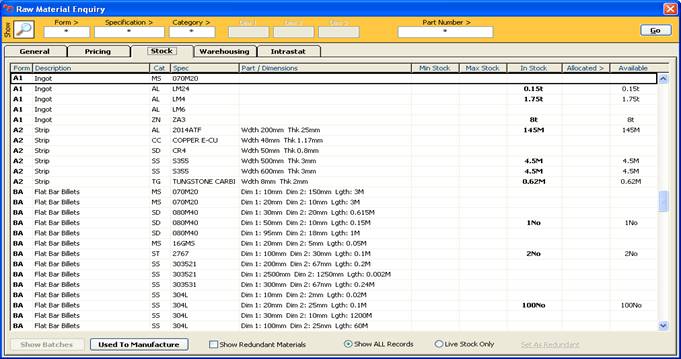

Raw Material Stock Control:

1st Manufacturing Raw Material Stock Control does not require meaningless Stock Codes to be allocated to different items instead it is categorised according to its:

- Material Category (Nickel, Stainless Steel, Copper, etc.)

- Form (e.g. Bar, Tube, Sheet, Hex, etc.)

- Specification (e.g. MSRR6524, AMS5707, etc.)

- Size (Metric or Imperial)

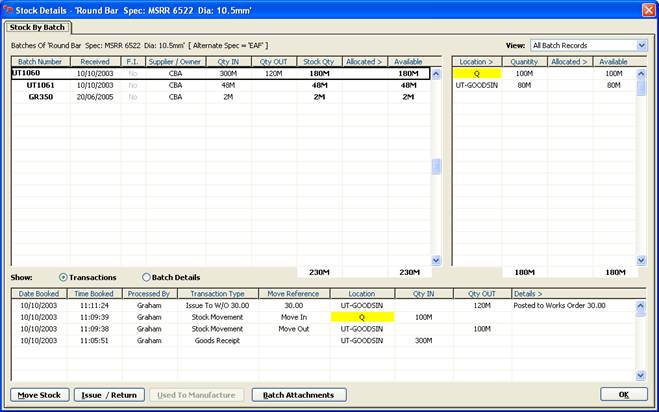

Against each Size of a particular Raw Material the Total Quantity In Stock, Available, On Order and Allocated is visible and this data can then be ‘drilled down’ to view the individual Batches and their respective Supplier, Purchase Date, Cost, Cast Number, Release Note Number, Quantity and Number of Lengths/Sheets ( by Stores Location ).

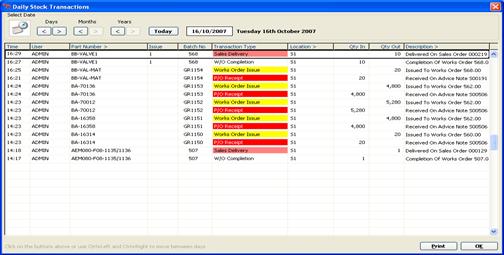

All standard types of Stock Movements (e.g. Goods Receipts, Goods Issued, Adjustments, etc.) are catered for.

Future demand, by week or month, is calculated ( via the M.R.P. report ) from the Forward Order demand suitably expanded for Assemblies and taking into account Manufacturing and Purchase Lead Times to facilitate the necessary Forward Ordering of Material to satisfy future demand.

Future demand, by week or month, is calculated ( via the M.R.P. report ) from the Forward Order demand suitably expanded for Assemblies and taking into account Manufacturing and Purchase Lead Times to facilitate the necessary Forward Ordering of Material to satisfy future demand.

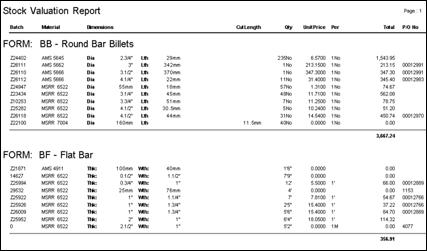

Material Traceability and Costing to Works Orders is dynamically generated as Material is booked out of Stores and onto Works Orders.

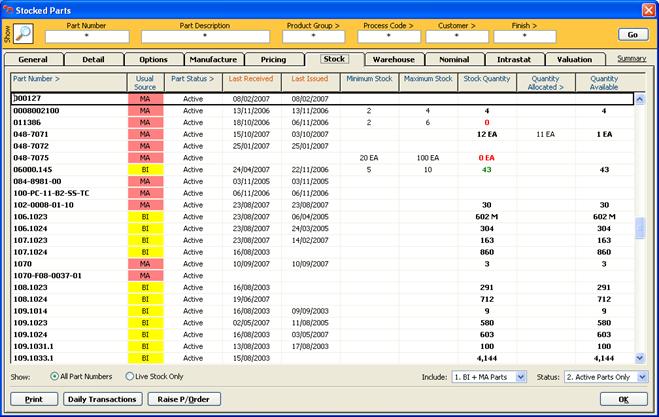

Finished Parts Stock Control:

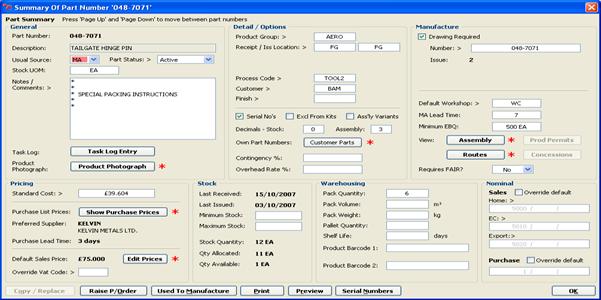

Similar control to the above is provided for Finished Parts ensuring that relevant traceability data is stored per Batch.

All Stock is identified by its Part Number from which Stocks can be seen at Part Number Issue level (with appropriate traceability data stored by Batch Number).

Full Transaction Movement History is maintained for all Parts and their associated Batches and as with Raw Material future demand is calculated from the Forward Order data expanded, where appropriate,

By Assemblies and Forward Orders.

All Purchased and Manufactured Parts are controlled, and traceable, through the Stock System even where items are Manufactured and immediately shipped to Customers.

Where Purchase Orders are raised through 1st Manufacturing the Parts or Raw Materials are quickly GRN’d (booked in) and all relevant details and costs are ‘inherited’ from their Purchase Order.

Full Audit Trail traceabilty and reporting of all Stock Movements is an inherent part of 1st Manufacturing.

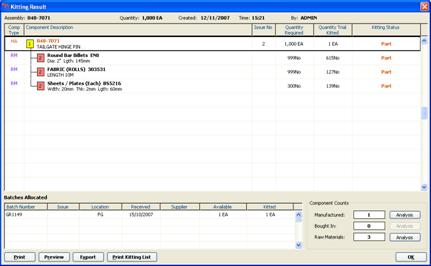

Trial Kitting facilities also available: