Manufacturing Instructions and Route Cards (Back)

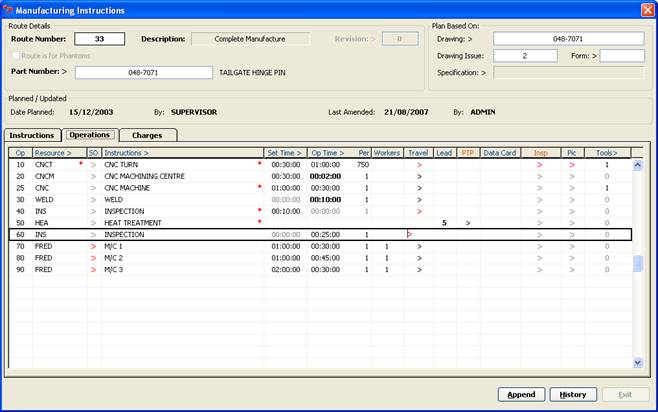

These Instructions comprise the individual Operation details of Set-Up Time, Operation/Cycle Time, Lead Time (for Sub-Contract) associated to the various Resource Codes that define the machines and processes provided by your company and its associated sub-contractors.

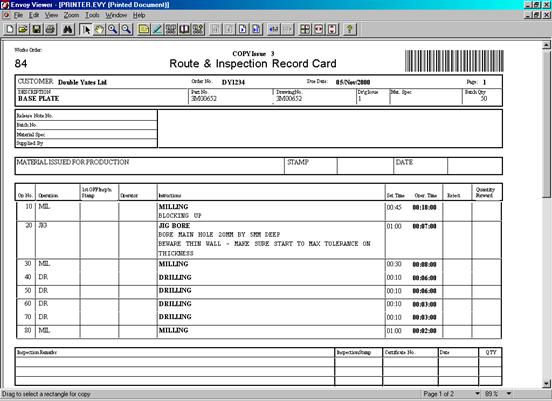

In addition to the standard Resource Descriptions (e.g. CNC Milling, Drilling, Bench/Assembly, etc.) the Planner may also specify more detailed Operation by Operation Instructions that will appear alongside the Operation when the Route Card is printed. In the case of Sub-Contract Operations these detailed Operation Instructions are automatically reproduced on the relevant Sub-Contract Purchase Orders as are the associated Batch Prices which are also brought forward from the Manufacturing Instruction database.

It is also possible to maintain more than one set of Manufacturing Instructions for a Part to cater for the situation where alternative Manufacturing Routes are possible.

Once Manufacturing Instructions are available the User may print off Route Cards for that Part in either stand-alone format or via the Works Order and Scheduling modules which will enable the Route Card to automatically reflect the Customer, Quantity, Due Date, Works Order Number, etc.

All printed Route Cards have the Works Order Number printed in a Bar Code format to facilitate the Shop Floor Data Capture options available within 1st Manufacturing.

When utilised in conjunction with the Estimating Module the above procedure is considerably simplified as Manufacturing Instructions can be automatically created straight from the Quotation. These Manufacturing Instructions inherit all relevant attributes of the Quotation but may then be expanded for actual Production use (e.g. Detailed Manufacturing Instructions may be added for some Operations).

All Manufacturing Instructions are associated with a specific Drawing Issue Release for the Part and these Issue Numbers are checked between Manufacturing Instructions, Quotation, Customer Order and Drawing Register to ensure that Route Cards can only be produced where all Issues agree.

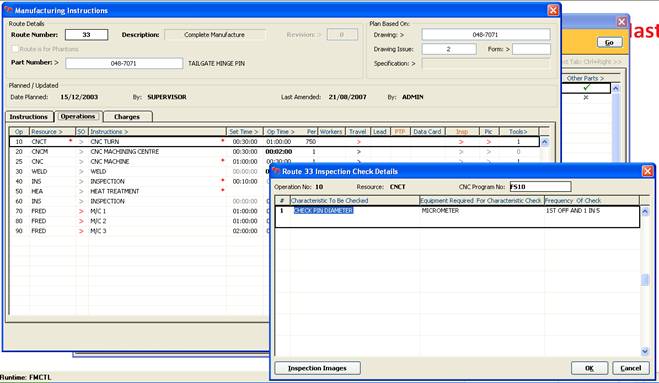

As well as the Manufacturing Instructions themselves, it is also possible to record details of an associated Data Card Reference, Operator Self-Inspection Check List, CNC Program Number or even to embed a Stage Drawing, Digital Photograph or Digital Video Clip within each Manufacturing Stage

All resulting in a Route Card similar to the following (or chosen from a library of over 42 alternate Route Card layouts as well as a fully customisable version):